We aim to create products that convey the charm of crocodile leather, which gives off an overwhelming aura, and continue to make products that are made in Japan.

Making the most of the presence of leather, we pay particular attention to every step of the process, from material selection to design and sewing, and our craftsmen sew every stitch with all their heart and soul.

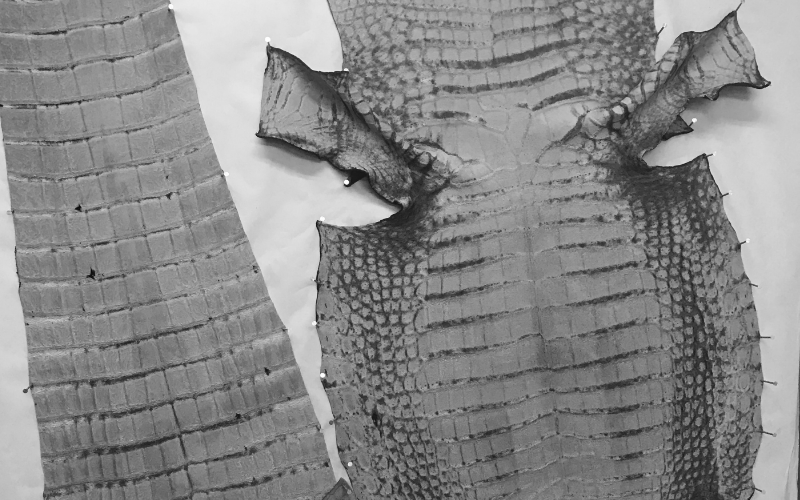

Crocodile selection

One thing I can tell you from working at an exotic leather tanning site is that crocodile leather has a much denser fiber than pig or cow leather.

The normal tanning process can take as little as 2-3 weeks for pigs, and 3-4 weeks for cows.

In comparison, crocodile leather usually takes about 3 months, but if it is tanned using chrome or tannin, or dyed with natural indigo, it takes about 4-5 months.

Crocodile Features

Dense fibers tend to be more durable and scratch resistant, so you can use it for a longer period of time than other leathers. The more you use it, the more the color changes, the more glossy and texture it develops, and the more it develops the so-called "flavor" that comes with age, so it will become an item that you will grow to love over the years. That is why crocodile is called the king of leathers, and it is no exaggeration to say that it is a leather that lasts a lifetime. Each piece is carefully finished.

PROCESS

Leather selection

We directly inspect the crocodiles in their place of origin (Africa, Australia), select the skins suitable for our products, import the raw skins, and then tan the skins domestically. We further select the skins before dyeing.

Tanning and dyeing

Raw hides are tanned at a domestic tannery (from hide to leather)

The photo below shows the tanning drum.

Wet blue (tanning process)

The leather is left to mature for 10 to 14 days without drying out, allowing the tanning agent to penetrate deep into the leather.

Drying process

In recent years, the method of laying the leather on a net has become mainstream, but as it uses a heater to dry the leather, it is efficient and takes a short time, but drying it too quickly can damage the leather. Therefore, to avoid damaging the surface of the leather, we lay it evenly on a board with the back side facing down, and dry it in the shade, avoiding direct sunlight, allowing it to dry slowly over a long period of time.

Sewing

We manage all the processes in-house, from cutting, stripping (thinning), edge stripping (sewing), sewing, and assembly, carefully stitching each stitch to ensure that the end user can use the product with attention to detail.

Finishing

The finished product is finally polished with wax and oil that we mix in-house, and delivered to the customer in the best condition.

KOKI HARADA

Influenced by his grandfather's leather industry, he grew up in an environment where he was exposed to the manufacturing process of various types of leather, including fur and reptile leather, and interacted with leather craftsmen from an early age. As a reptile tanner, mainly focusing on crocodiles, he has worked on many leather products for long-established overseas fashion houses and for custom-made products. With a focus on quality, he became independent as a factory that handles all production from material selection to cutting and sewing. Every year, he visits local leather farms in Africa, Australia, Southeast Asia, etc.

We have personally selected high-quality crocodile leather. Due to its special structure and delicacy, there are said to be only 20 or so tanneries in the world that handle crocodile leather. Among them, Japanese craftsmen are able to carry out the entire process from material selection, cutting, to sewing.